Maker

The intricate task of replacing the iBook G4 hard disk.

First, I connected the new disk to the Mac via USB, and with the help of Carbon Copy Cloner, I created a perfect copy of the old disk, which was still inside the computer. Then, after many layers and countless screws (pictures below), I finally reached the disk and replaced it.

The operation took me a good number of hours, and despite the flawless boot, the sleep and wake function was not working when closing and opening the lid. It took me a while to figure it out, but the culprit was one of the magnets not being correctly aligned. Here we go again. To get there, I had to take off some layers and screws one more time.

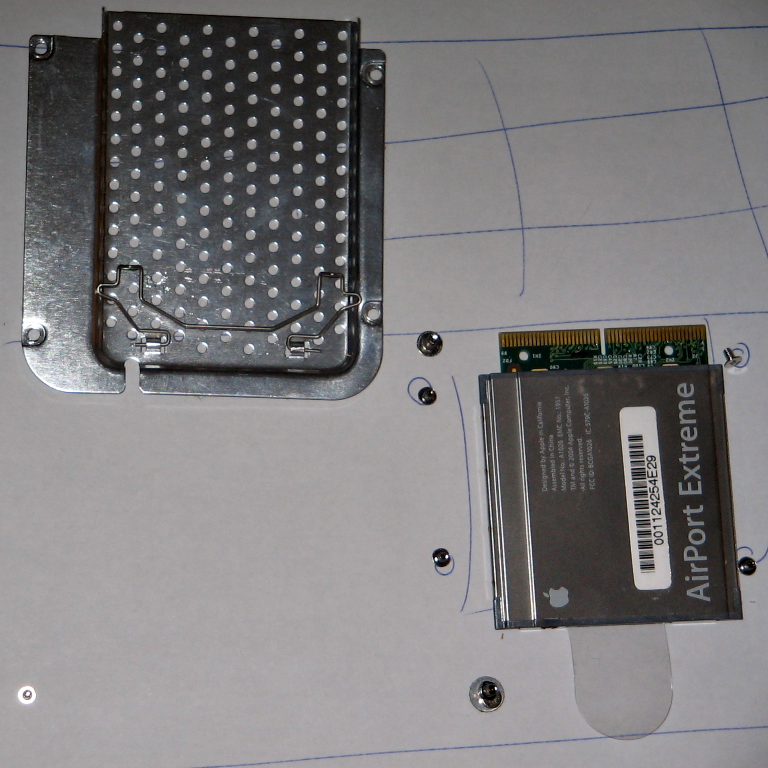

The next problem on the list was the Wi-Fi not working. I checked the Airport Extreme card, which is easily accessible below the keyboard, and everything looked fine. After several hours of troubleshooting the operating system without any success, I realized how late it was and went to bed.

By the way, when you feel stuck, it’s a good idea to take a break or switch to a different project. It always works for me, at least.

The Next Day

I’m not going to lie to you. Throughout the day at work, I wondered what could be wrong with my computer. If everything was fine with the operating system, maybe I have damaged the Wi-Fi card.

Back at home, I decided to check the card again, and when I touched it, I noticed that the antenna cable connector was not completely pushed in. The moment I pressed it and heard the click, I knew the Wi-Fi would be fine.

Wow, what a mission!

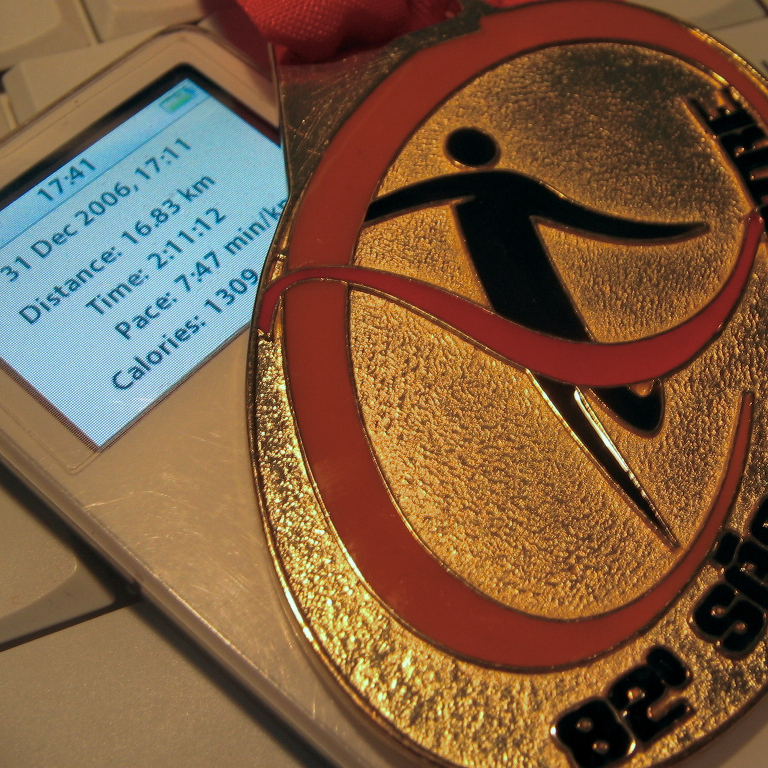

First 15K (using my Nike+iPod hack)

Yesterday, I completed my first 15K!

It was very difficult, and my time was terrible, but I am so happy to have completed this race. It has not been that long since I started jogging, with my first small victory being running around a park with less than a third of this distance.

I’ve been using the hack below almost since I bought the Nike+iPad and I never had a problem. I’m pretty happy with it.

Nike+iPod hack

Even though I don’t like Nike running shoes, I love running with my iPod, so I got the Nike+iPod tracker as soon as I could. But since it was announced, I have been trying to figure out how to attach it to my non-Nike shoes. Inspired by some adaptors being sold online, I came up with a simple hack.

These are just two sides of a velcro trip attached to each other on one end. Because one is facing the other, the attachment sides will also meet on the opposing end, closing the loop after passing it under the laces. I don’t really think it was necessary, but I stitched the center part just in case. As for the Nike+iPod, I glued it using 3M double-sided tape.